Rudder Control Cables.

Time to fit the rudder control cables to the rudder.

Line the front of the black loop of the control cable with the hole in the pedal runner as shown in the photograph above. Place a clamp on the cable to stop it pulling back towards the rudder.

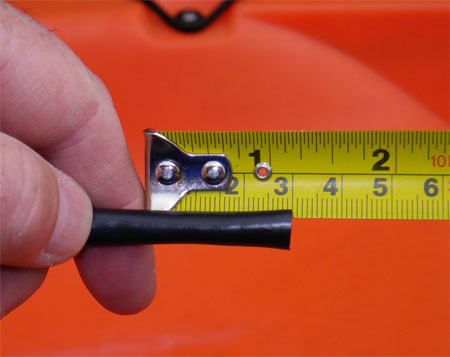

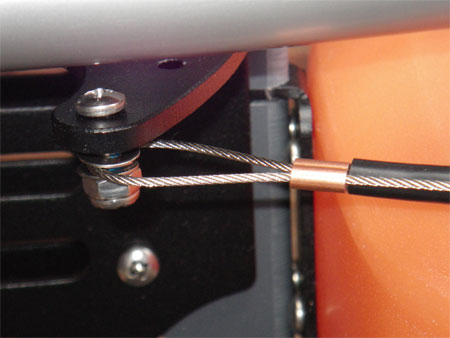

Take the length of shrink tube supplied with the rudder kit and cut two 3cm lengths. and slide over the wire at the rudder end of the kayak, then slide on the brass crimp, wrap the wire around the bolt on the rudder control arm, ensure that the wire goes between the two washers, run the wire back through the crimp and slide the crimp towards the rudder control arm.

With the rudder up and in its rest so that it can't twist, pull the wire tight and crimp twice once at each end of the crimp. trim off the excess wire with a pair of cutters close to the crimp.

Slide the shrink tube over the crimp and using a lighter apply heat to shrink the tube around the wire and crimp, be careful not to get the flame to close to the tube as it will burn or start to tear and melt.

Now you have completed the first side, repeat the exercise for the other control cable.

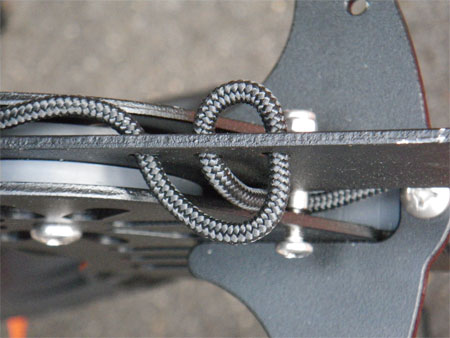

From the cockpit you need to be able to raise and lower the rudder, so its time to fit the control line. Loop the long length of black line supplied with the rudder kit, as shown in the image above, the rudder is up and laying in its rest. The line facing the bow is taken under the bolt with the roller on the right hand side of the blade. The line running to the rear is taken around the grey wheel on left hand side of the rudder, all the way around and taken over the same bolt with roller that the right hand line went under.

I then ignore the instructions supplied with the kit and run the line directly towards the cockpit on the left hand side. Loop the top line around a roller block as shown in the picture, I have attached a piece of short bungee to the roller block, this not only helps when joining the two ends of the line, but also takes up any slack.

Its worth sitting in the kayak at this stage and having a fiddle to find the best position for the block. You may have to fiddle with the lines a little so that you join them as far back in alignment with the tankwell. Mark the position of the pad eye.

Tie an overhand knot both sides of the line this is where you will grip to pull the line to raise and lower the rudder, I have added a couple of plastic rope balls to make it a little more comfortable. The position of these knots will depend on your arm length and what is comfortable for you.

Using a Blood Knot join the two ends of the rope together, check the position of the pad eye and ask somebody to hold it whilst you raise and lower the rudder ensuring that you have enough clearance between the knots in the line and the block. Mark the pad eye for drilling.

Drill and fit the pad eye, adding a bit of silicone sealant to the holes before rivetting.

If happy trim the excess line on the Blood Knot and seal the ends with a lighter.

The Clamcleat neets to be fitted in line with the lower loop of the control line so that the rudder can be locked in the down position, drill and rivet.

Disclaimer:

Installing hardware may cause damage and/or void manufacturer warranties.

The information we provide is a free reference guide only. The author of this information, sponsors and the owners of the website that host this information are not liable for any problems or issues that arise from the use of this information. Users of this information hereby acknowledge that all use of this information is done by their own free will, at their own sole risk, understanding that injury or death could occur.